After audiences enjoyed the final episode of The Celebrity Traitors last Saturday, the hunt now begins in real life. In this thrilling new immersive experience in Covent Garden, guests step into the world of The Traitors, completing missions, navigating mind games at The Round Table, and testing their strategy in a battle of deceit and loyalty.

Lighting designer Elliot Griggs was appointed to bring the tension, drama, and theatricality of the hit TV show into a fully immersive live environment. He approached White Light (WL) to supply the lighting fixtures.

“We wanted to bottle the tension and drama that everyone loves from the TV show and boil it down into the live experience,” explains Elliot. “We couldn’t exactly rebuild Ardross Castle in Covent Garden, but we could take plenty of design cues to give as much of the iconic look and feel as we could.”

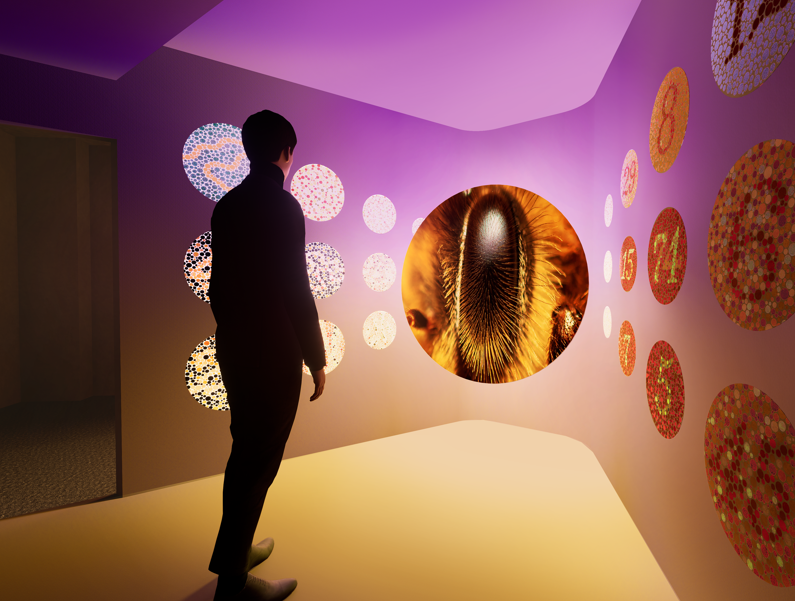

Lighting plays a pivotal role in shaping the experience, guiding guests through dimly lit corridors, past eerie portraits and suits of armour, and into the high tech Round Table rooms.

“The Round Table is where much of the experience takes place, and so is the most technically advanced room in the experience,” says Elliot. “These rooms use lighting to go between day, night and into challenge states as well as heightening the many moments of tension throughout the game.”

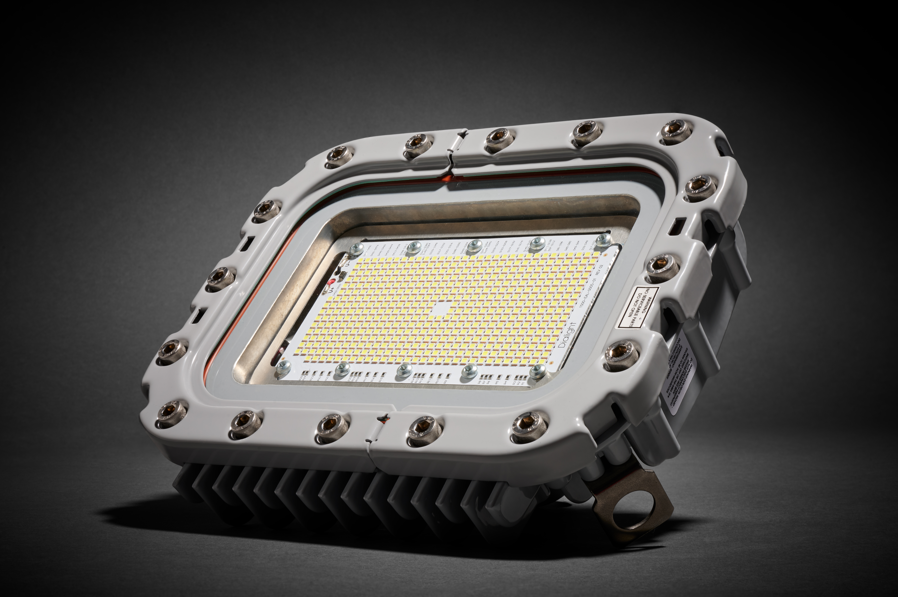

To meet the demands of this complex production, WL supplied a carefully selected range of fixtures tailored to the unique requirements of each space. Over 120 Chauvet ColorDash Accent 3 units were installed—one for each player seat—providing precise control and dynamic effects. Additional Chauvet fixtures, including ColorDash H7X Pars, Slimbanks, and Eve P160s, were used to enhance colour rendering and create impactful photo opportunities. For broadcast-quality lighting in the Round Table rooms, Elation KL Fresnel 4 FCs were added to the rig. Atmospheric effects were delivered using Le Maître hazers, chosen for their low fluid consumption and minimal residue. Data distribution was managed via Obsidian Netron EN12, enabling remote triggering and emergency recalls, while LED pixel control was handled through Enttec Pixellator Minis and PLinks. At the heart of the system, an ETC EOS console orchestrated over 140 cue stacks and nearly 4,000 cues, ensuring seamless transitions and immersive gameplay.

“All the show areas required LED with 16-bit control, excellent colour rendering and refresh rates that would be suitable for camera as we transmit every game to its linked lounge so that banished and murdered players are able to watch the rest of the game play out, and take part in extra challenges. ” Elliot explains. “Everything was selected for specific reasons – from the Le Maître hazers for their low fluid consumption, to the Netron EN12 for its remote triggering and recalls.”

The experience is powered by Clockwork Dog’s COGS system, allowing actors to operate the show live via a custom tablet interface. This seamless integration of lighting, sound, and video ensures that each game runs smoothly, with technical staff on hand only for support.

“The show itself is extremely technically complex, with eight games running simultaneously on one lighting console,” says Elliot. “Every player has their own ColorDash Accent 3 spot which tracks their progress, and almost every button and interaction in the room has some form of live response.”

Audience reactions have been overwhelmingly positive. “Seeing people’s excitement as they walk into the Round Table room or Traitors Tower is really great to see,” Elliot shares. “My favourite moment is during player introductions – the light above their seat brightens with a deep rumbling whoosh, and the whole table lets out a collective ‘ooh’.”

WL’s Key Account Manager, Ally DeCourcy comments: “It’s been great to collaborate with Elliot on this project and supply the fixtures for this amazing new immersive experience! We’ve worked with Elliot on past theatre productions and it’s great we could help him fulfil his creative vision by sourcing the right equipment.”

WL is proud to have played a part in bringing this ambitious and technically sophisticated experience to life. Our collaborative approach and commitment to technical excellence ensured that the lighting design not only supported the gameplay but elevated the entire experience.

Will you experience it for yourself and discover whether you’re a Faithful… or a Traitor?